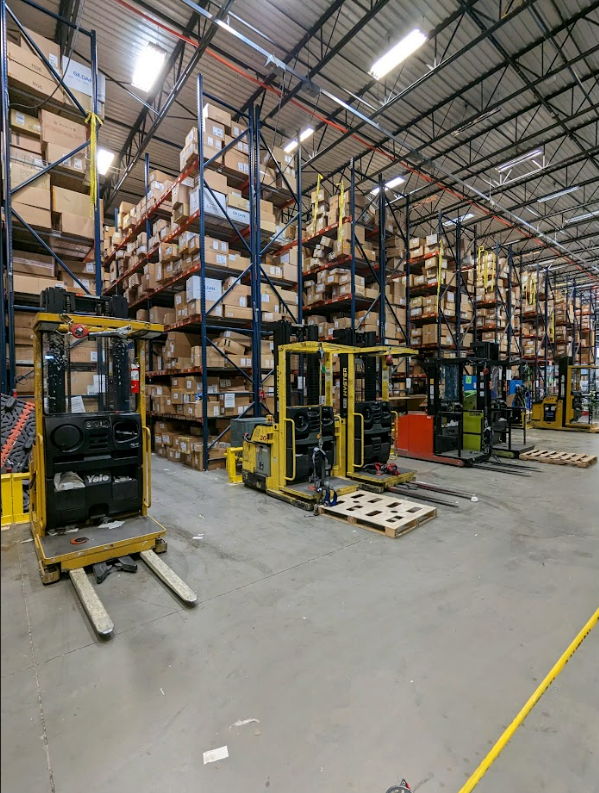

In today’s fast-paced market, the efficiency of a company’s supply chain and product stocking strategies are crucial for success. Warehouses, as the backbone of the supply chain, are evolving to meet the dynamic demands of consumers and businesses alike. Here’s a look at how companies are revolutionizing their approach to stocking products in warehouses.

Data-Driven Inventory Management

Modern warehouses rely heavily on data analytics to predict consumer trends and stock products accordingly. By analyzing sales data, market trends, and consumer behavior, companies can anticipate demand and adjust their inventory in real time. There’s a huge advantage by keeping a daily log of inventory, because longer intervals can lead to miscalculations and more human error.

Automated Replenishment Systems

Automation plays a key role in inventory management. Automated replenishment systems ensure that stocks are maintained at optimal levels, reducing the risk of overstocking or stockouts. This technology facilitates timely restocking, maintaining a steady flow of products.

Lean Inventory Practices

Many companies are adopting lean inventory methods, focusing on keeping stock levels minimal yet sufficient. This approach reduces storage costs and minimizes the risk of unsold inventory, particularly for products with short shelf lives.

Just-In-Time (JIT) Inventory

The JIT inventory strategy aligns closely with lean principles. JIT only brings in materials as they are needed for production. This minimizes the 8 key wastes in lean manufacturing – overproduction, waiting, transportation, inventory, motion, over-processing, defects, and unused employee creativity. By aligning inventory levels precisely with production demands, JIT significantly improves efficiency and responsiveness across the entire manufacturing process.

Vendor-Managed Inventory

Collaboration with suppliers through vendor-managed inventory (VMI) systems allows for better synchronization of supply and demand. Suppliers take a more active role in managing stock levels, improving efficiency in the supply chain.

Diversified Supplier Networks

To avoid disruptions, companies are diversifying their supplier networks. This strategy ensures a more reliable supply chain, allowing warehouses to maintain a consistent stock of products despite external challenges.

Sustainable Stocking Practices

Sustainability is becoming a priority. Companies are increasingly mindful of their environmental footprint, choosing eco-friendly packaging and optimizing transportation to reduce emissions. This is an increasingly popular trend in product stocking that affects the supply chain.

E-Commerce Integration

The rise of e-commerce has led warehouses to adapt their stocking strategies. Quick processing and delivery of online orders require efficient stock management and layout optimizations in warehouses.

Seasonal and Event-Based Stocking

Warehouses are increasingly adapting to seasonal shifts and events. Stocking products based on seasonal demand ensures that warehouses are not burdened with unsold inventory post-season.

Advanced Forecasting Tools

The use of advanced forecasting tools allows companies to better predict future demand, enabling more accurate stock levels and reducing the risk of overstocking or understocking in their warehouses.

The evolution of supply chain and product stocking practices is a testament to the adaptive nature of businesses in response to changing market dynamics. By leveraging technology, data analytics, and sustainable practices, companies are not only improving efficiency but also enhancing customer satisfaction. The future of warehousing lies in smart, flexible, and responsive stocking strategies that can meet the demands of a rapidly evolving marketplace.

Upgrade Your Warehouse Stocking Strategies With Pallet Rack World’s Innovative Solutions

From advanced racking systems to customized storage options, we cater to all your supply chain needs. Enhance efficiency, reduce costs, and streamline your operations. Explore our diverse range of products and services, tailored to optimize your warehouse management. Let’s build a smarter, more secure warehouse together!